3D Printing in Education

3D Printing is a printing technology evolution which lets anyone create a 3D model of an object/product using a 3D Printer.

Let’s understand – what are the phases that a product goes through before it is manufactured using 3D Printer (Additive Manufacturing).

Ideation: In this phase, the purpose, usability, and the probable design of the product is discussed and finalised.

Prototyping: After ideation, a sample prototype of the product is created on a software.

Manufacturing: Once the design of the product is finalised, it is manufactured using 3D Printer – it starts with an empty work area and typically extrudes or melts material onto it to create an object.

Applications of 3D Printing

3D printing is used in sectors like architecture, construction, healthcare, food industry, education, aeronautics, robotics etc.

In the future, 3D printers will also be used to create human tissue and organs. This will need medical and engineering experts to collaborate.

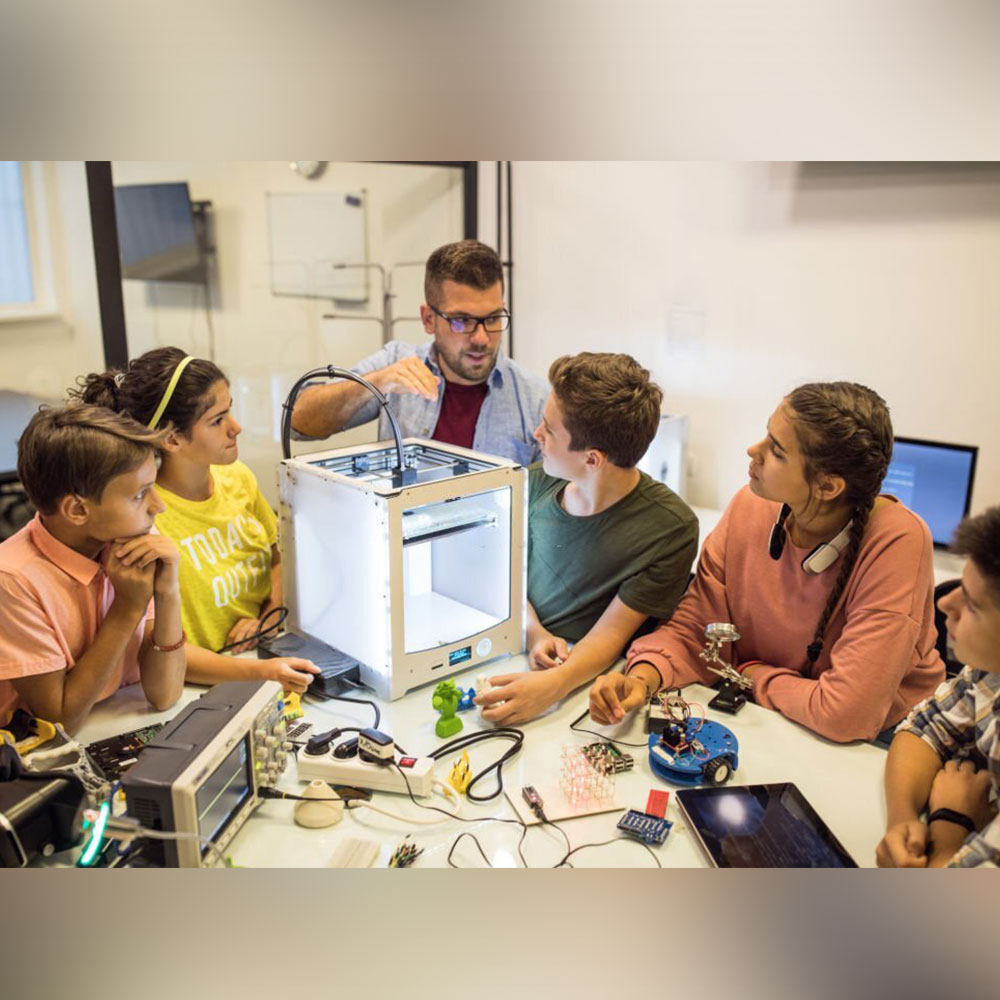

3D Printing in Education

Affordable and easy-to-use 3D printers, integrated lesson plans, online resources and extensive training programs have made 3D printing, a popular learning tool in education.

It allows teachers and students to realize ideas, create projects, build practical skills, and engage in fun and interactive ways.

Integrating 3D printing into the curriculum will make the lessons more powerful. While skills and content will vary depending on age, 3D printing can be taught across different grade levels.

Here’s how Students can use a 3D Printer in the Classroom

- Graphic Design students can print out 3D versions of their artwork

- Biology students can take 3D prints of cells, viruses, organs etc.

- History students can take 3D prints of historical artifacts to examine

- STEM students can take 3D prints of the prototypes they’ve designed to solve real-world problems

3D Printing Technology Promises a Productive Educational Experience

Engages students

Being passive consumers of information on a screen in the conventional classrooms, students find learning uninteresting. With 3D printing technology, they become active and engaged participants through the conception, design, and execution of their design thinking projects and interacting with the 3D printer and their teacher.

Better understanding of the design process

Students get the opportunity to experience their projects from the model stage to actual creation of the model using 3D printing; it improves their understanding of the design process as they gain hands-on experience – from conception to creation of the model/prototype.

Builds visual learning environments

Educators can use the objects generated with 3D printers to explain concepts to students using real-time information. By creating a visual learning environment, it allows students to see and touch the projects simultaneously.

Strengthens problem-solving skills

3D printers in the classroom give students the opportunity to learn how different 3D printers work, how to operate them, and how to troubleshoot and solve problems. Students develop resilience and perseverance which helps them to solve their own problems in life.

Encourages innovation and creativity

Maker Labs as Do it yourself (DIY) space in schools provide students with the platform to ideate, design, collaborate and create new things. 3D printers enable students to put their ideas into practice, innovate and create products through teamwork.

Prepares students for the future

3D printing being one of the top emerging technologies, students can strengthen their career prospects by learning and leveraging this cutting-edge technology. To make students future ready, schools are integrating 3D technology in their curriculum and developing new study programs based on 3D printing technology. Some of the future careers in 3D printing include 3D Organ and Prosthetic Designers, 3D Printing Software Developers, 3D Printing Auto Mechanics and Engineers.

Here’s how to prepare an object for 3D printing in the classroom

The three main steps in any product formation include ideation, prototype, and manufacturing. Ideation and prototyping are done either through physical modelling or on software. One such software is Blender that can be used to prototype a 3D object.

1) Make sure the units used to create the model are set correctly. Any 3D model you create, needs to have appropriate dimensions like inches.

2) Make sure the designed 3D object lays flat. This is to ensure that the filament gets sufficient support during printing. It also makes sure there is only minimum wastage. You can create a pocket mobile stand with hinges.

3) Double check to make sure the object is correctly sized.

A 3D printing software supports several file formats. The most commonly used file format is .stl.

This file can be opened in any 3D printing software, depending on the 3D printer used. A 3D printing software reads the .stl file and slices it in layers to prepare it for printing.

4) Once the 3D printing process is complete, the object is assembled and is ready for use.

At ICT 360, we provide advanced tech curriculum for schools – grades 1-10 – for AI, AR, VR, Coding, Media Design, App Design, Game Design, Web Design, 3D Printing, Robotics, IoT, Cloud Computing and all futuristic technologies to enable students to become Innovators, Collaborators and Problem-Solvers.

ICT 360 serves as a one stop solution for all ICT requirements of a school. With NEP aligned & STEM accredited ICT curriculum – this unique platform offers Teacher Development Trainings with Certifications, Project PPTs, Lesson Plans, Assignments, Learning Resources, Technical Support, Assessments, Reports, and LMS for students and teachers for synchronous & asynchronous learning to equip them with 21st century skills and prepare them for the tech-driven future.